Duramax Hyamp torches

Designed for durability and reliability, Duramax® Hyamp™ torches are built to handle the full 125-amp output of the Powermax125® plasma cutting system and are also compatible for use on lower amp Powermax® systems. Duramax Hyamp torches are available for handheld and machine cutting and gouging, and robotic cutting. In addition, Duramax Hyamp Long torches are available in .6 m (2′), 1.2 m (4′), and 1.83 m (6′) lengths providing extra reach and durability for heavy-duty applications like scrapping, plate skeleton removal from cutting tables and infrastructure repair or reconstruction.

Duramax Hyamp torches are available with an extensive array of specialty consumable options that perform a variety of applications such as gouging, fine feature cutting, extended reach cutting, precision gouging, cutting flush to base materials (flush cutting), and marking.

Torch information

Applications

Drag cutting

For dragging the torch directly across the work piece

Fine feature cutting

For narrow kerf width with minimal dross and heat affected zone

Flush cutting

For cutting closer to base materials using a 45 degree

Max control gouging

For precise metal removal, shallower gouge profiles and light metal washing

Max removal gouging

For aggressive metal removal, deep gouge profiles, and extreme metal washing

Mechanized cutting

For portable automation and table cutting

Benefits

For hand cutting and gouging jobs

Duramax® Hyamp™ 85° and 15° hand torches are well suited for most hand cutting and gouging jobs. The ergonomic design of the 85° torch is perfect for normal cutting, while the 15° torch directs heat away from the operator during heavy gouging and enables cutting overhead or in hard-to-reach areas.

For machine jobs

Duramax Hyamp 180°, full-length machine torches work with a wide variety of CNC cutting tables, track cutters, and pipe-cutters. Mini machine torches are perfectly suited for lighter tables and pipe cutting situations where the full-length torch is too long. Duramax Hyamp machine torches have a larger diameter and do not have a gear rack.

For robotic jobs

The light weight, small size and built-in positioning features of Duramax Hyamp robotic torches enable easy integration and operation with light robot arms. An optional clamp speeds integration.

For heavy-duty applications

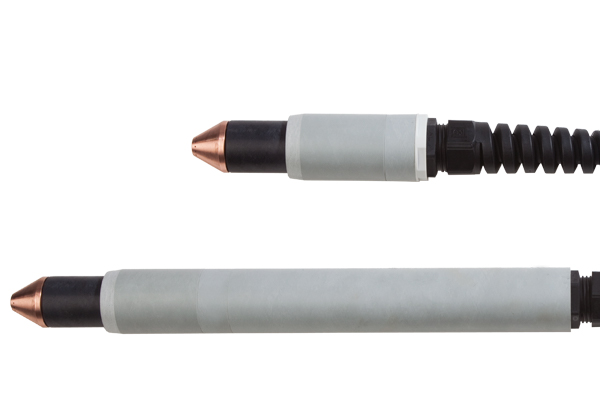

Duramax Hyamp Long torches offer extra reach and durability for heavy-duty applications like scrapping, plate skeleton removal from cutting tables, and infrastructure repair or reconstruction. .6 m (2’) and 1.2 m (4’) Long torches include a carry bag for storing the torch. The 1.2 m (4’) and 1.83 m (6’) Long torches include an adjustable position auxiliary handle.

Buying information

Visit our where to buy page to find a potential partner, or contact Hypertherm directly if you need further assistance.

Duramax Hyamp Long torch configurations

| Torch length, head angle | |||||||

|---|---|---|---|---|---|---|---|

| 0,6 m (2′), 45° | 0,6 m (2′), 90° | 1,2 m (4′), 45° | 1,2 m (4′), 90° | 1,8 m (6′), 90° | 1,8 m (6′), 45° | ||

| Torch lead length | 7,6 m (25′) | 059562 | 059563 | 059567 | 059568 | 059623 | 059758 |

| 15,2 m (50′) | 059579 | 059580 | 059581 | 059582 | 059624 | 059759 | |

| 45 m (150′)* | 059667 | 059668 | |||||

* 150 foot torches are only compatible with Powermax125 built after November 14, 2017 (serial number 125-007944 or higher) or that have had the DSP board replaced with a board built after this date.

Mechanical teach tool aids programming

Optional mechanical teach tool allows you to touch the plate while programming cutting and pierce heights.

Robotic clamp assembly kit (#228806)*

Robotic teach tool kit (#229832)*

*Duramax Hyamp robotic