XPR170 plasma cutting system

Delivering next generation X-Definition® processes from very thin up to mid-range thicknesses, the XPR170® expands plasma capabilities and opportunities in ways never before possible.

With unmatched X-Definition cut quality on mild steel, stainless steel, and aluminum, XPR170 increases cut speed, dramatically improves productivity, and slashes operating costs. New ease-of-use features and engineered system optimization make XPR® easier to run with minimal operator intervention, while also ensuring optimal performance and unmatched reliability.

System information

Benefits

Industry-leading X-Definition cut quality

The XPR advances HyDefinition® cut quality by blending new technology with refined processes for next generation, X-Definition cutting on mild steel, stainless steel, and aluminum.

-

Consistent ISO range 2 results on thin mild steel

-

Extended ISO range 3 cut quality on thicker mild steel and stainless steel

-

Superior stainless steel cut quality

-

Superior results on aluminum using Vented Water Injection™ (VWI)

Optimized productivity and reduced operating costs

-

Significantly reduced operating costs than previous generation technology

-

Increased cut speeds on thicker materials

-

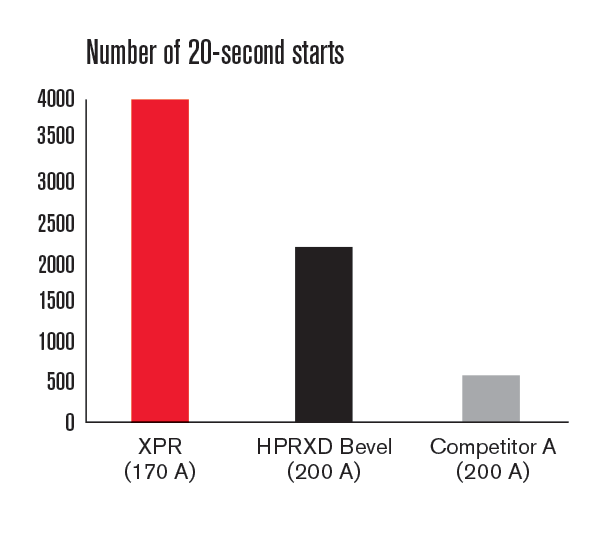

Dramatic improvement in consumable life on mild steel applications

-

Thicker piercing capability than competitive plasma systems

-

XPR automated gouging minimizes or eliminates grinding compared to carbon arc gouging, producing weld-ready parts faster with cleaner gouge profiles

Engineered system optimization and ease of use

-

Ramp down error protection significantly increases realized consumable life

-

Automatic system monitoring and specific troubleshooting codes for improved maintenance and service prompts

-

EasyConnect™ torch lead and one hand torch-to-receptacle connection for fast and easy change‑outs

-

QuickLock™ electrode for easy consumable replacement

-

The web interface tool can be accessed via Wi-FI and Ethernet LAN in the power supply for system monitoring and service

-

Built-in IIoT (Industrial Internet of Things) via Ethernet LAN and MTConnect® enables remote data access for smarter monitoring from anywhere in the world

-

Manual Set-Mode is ideal for straightforward applications like gouging and off-table beveling; it retains your last setup for faster, repeatable workflows and simplifies set up and operations without the need for CNC/PLC integration

Advanced process control and delivery

Four console options – Core™, CorePlus™, Vented Water Injection™ (VWI™) and OptiMix™ – offer unmatched mild steel cut quality with each console delivering successively enhanced cutting capabilities on stainless steel and aluminum. All consoles can be fully controlled through the CNC for high productivity and ease of use.

Gas-connect console gases/fluids

| Core | CorePlus | Vented Water Injection (VWI) | OptiMix | |

|---|---|---|---|---|

| O2/N2/Air | X | X | X | X |

| Ar | X | X | X | |

| F5/Ar/H2O | X | X | ||

| H2-N2-Ar mixing | X |

Specifications

| Maximum open-circuit voltage (U0) | 360 VDC |

| Maximum output current | 170 A |

| Maximum output power | 35.7 kW |

| Output voltage | 50 VDC–210 VDC |

| 100% duty arc voltage | 210 V |

| Duty cycle rating | 100% at 35.7 kW, 40° C (104° F) |

| Operational ambient temperature range | -10° C–40° C (14° F–104° F) |

| Power factor | 0.98 at 35.7 kW |

| Cooling | Forced air (Class F) |

| Insulation | Class H |

| EMC emissions classification (CE models only) | Class A |

| Lift points |

Top lift eye weight rating 454 kg (1,000 lb.) Bottom lift truck slots |

Operating data

| Mild steel | mm | inches | |

|---|---|---|---|

| Pierce capacity | (argon-assist shield gas) | 40 | 1–9/16 |

| (standard air shield gas) | 35 | 1–3/8 | |

| Severance | 60 | 2–3/8 | |

| Stainless steel | |||

| Pierce capacity | 22 | 7/8 | |

| Severance | 38 | 1–1/2 | |

| Aluminum | |||

| Pierce capacity | 25 | 1 | |

| Severance | 38 | 1–1/2 | |

This does not represent a complete list of processes or thicknesses that are available.

| Console | Cutting gases | Current (Amperage) | Thickness (mm) | Approximate cutting speed (mm/min) |

Thickness (in.) | Approximate cutting speed (ipm) |

|---|---|---|---|---|---|---|

| Mild steel | ||||||

| Core™, CorePlus™, VWI™, and OptiMix™ | O2 plasma | 30 | 0.5 | 5348 | 0.018 | 215 |

| O2 shield | 3 | 1153 | 0.135 | 40 | ||

| 5 | 726 | 3/16 | 30 | |||

| O2 plasma | 50 | 3 | 3820 | 0.105 | 155 | |

| Air shield | 5 | 2322 | 3/16 | 95 | ||

| 8 | 1369 | 5/16 | 55 | |||

| O2 plasma | 80 | 3 | 5582 | 0.105 | 225 | |

| Air shield | 6 | 3048 | 1/4 | 110 | ||

| 12 | 1405 | 1/2 | 55 | |||

| O2 plasma | 130 | 3 | 6502 | 0.035 | 240 | |

| Air shield | 10 | 2680 | 3/8 | 110 | ||

| 38 | 256 | 1–1/2 | 10 | |||

| O2 plasma | 170 | 6 | 5080 | 1/4 | 200 | |

| Air shield | 12 | 3061 | 1/2 | 115 | ||

| 25 | 1175 | 1 | 45 | |||

| 60 | 152 | 2–3/8 | 6 | |||

| Stainless steel | ||||||

| Core, CorePlus, VWI, and OptiMix | N2 plasma | 40 | 0.8 | 6100 | 0.036 | 240 |

| N2 shield | 3 | 2683 | 0.105 | 120 | ||

| 6 | 918 | 1/4 | 32 | |||

| VWI and OptiMix | F5 plasma | 80 | 3 | 4248 | 0.135 | 140 |

| N2 shield | 6 | 1916 | 1/4 | 70 | ||

| 12 | 864 | 1/2 | 34 | |||

| N2 plasma | 170 | 10 | 1975 | 3/8 | 80 | |

| H2O shield | 20 | 978 | 3/4 | 40 | ||

| 38 | 434 | 1-1/2 | 17 | |||

| OptiMix | H2-Ar-N2 plasma | 170 | 10 | 1975 | 3/8 | 80 |

| N2 shield | 12 | 1735 | 1/2 | 65 | ||

| 38 | 256 | 1-1/2 | 10 | |||

| Aluminum | ||||||

| Core, CorePlus, VWI, and OptiMix | Air plasma | 40 | 1.5 | 4799 | 0.036 | 240 |

| Air shield | 3 | 2596 | 1/8 | 85 | ||

| 6 | 911 | 1/4 | 32 | |||

| VWI and OptiMix | N2 plasma | 80 | 3 | 3820 | 1/8 | 140 |

| H2O shield | 6 | 2203 | 1/4 | 80 | ||

| 10 | 956 | 1/2 | 28 | |||

| N2 plasma | 130 | 6 | 2413 | 1/4 | 95 | |

| H2O shield | 10 | 1702 | 3/8 | 70 | ||

| 20 | 870 | 3/4 | 35 | |||

| N2 plasma | 170 | 10 | 1994 | 3/8 | 80 | |

| H2O shield | 20 | 978 | 3/4 | 40 | ||

| 38 | 434 | 1-1/2 | 17 | |||

| OptiMix | H2-Ar-N2 plasma | 170 | 10 | 3334 | 3/8 | 135 |

| N2 shield | 20 | 1213 | 3/4 | 50 | ||

| 38 | 384 | 1-1/2 | 15 | |||

Buying information

Visit our where to buy page to find a potential partner, or contact Hypertherm directly if you need further assistance.

Resources

Manuals and documents

XPR torch

| Part number Standard |

Part number Standard Bevel/Robotic |

Part number Bevel/Robotic |

Description |

| 428383 | 428825 | 428831* | Lead: 6.6′ |

| 428384 | 428826 | 428832* | Lead: 8.2′ |

| 428385 | 428827 | 428833* | Lead: 9.8′ |

|

428386 |

428828 | 428834* | Lead: 11.5′ |

| 428824 | 428829 | 428335* | Lead: 13.1′ |

| 428387 | 428830 | 428836* | Lead: 4.8′ |

| 428978** | 428979** | Lead: 20′** | |

| 428916 | Lead: Thru arm robotic 11.5′ | ||

| 428918 | Lead: Thru arm robotic 14.8′ | ||

| 420500 | Torch mounting sleeve: Standard | ||

| 420501 | Torch mounting sleeve: Short | ||

| 420502 | Torch mounting sleeve: Extended | ||

| 420788 | Rotational torch mounting sleeve: Short | ||

| 420789 | Rotational torch mounting sleeve: Medium | ||

| 420790 | Rotational torch mounting sleeve: Extended | ||

| 420220 | Quick-disconnect torch receptacle | ||

| 420221 | Quick-disconnect XPR torch | ||

| 420368 | Water tube |

* Bevel/Robotic leads sets 428831-428836 include an extended 1.2 m (48″) strain relief.

** The 6 m (20′) lead is compatible only with console gas assemblies that are 7.5 m (24.6′) or less.

XPR consumables

Nozzles and electrodes are available in various quantities. Please contact an authorized Hypertherm distributor to place your consumables order. Your consumables may not look exactly like the pictures.

Mild steel

| Amperage | Process | Shield cap |

Shield | Nozzle retaining cap |

Nozzle | Swirl ring | Electrode | Water tube |

|---|---|---|---|---|---|---|---|---|

| 30 A | O2/O2 | 420200 | 420228 | 420365 | 420225 | 420407 | 420222 | 420368 |

| 50 A | O2/Air | 420200 | 420237 | 420365 | 420234 | 420233 | 420231 | 420368 |

| 80 A | O2/Air | 420200 | 420246 | 420365 | 420243 | 420242 | 420240 | 420368 |

| 130 A | O2/Air | 420200 | 420255 | 420365 | 420252 | 420242 | 420249 | 420368 |

| 170 A | O2/Air | 420200 | 420513 | 420365 | 420261 | 420260 | 420258 | 420368 |

Non-ferrous

| Amperage | Process | Shield cap |

Shield | Nozzle retaining cap |

Nozzle | Swirl ring | Electrode | Water tube |

|---|---|---|---|---|---|---|---|---|

| 40 A | N2/N2 | 420200 | 420291 | 420365 | 420288 | 420314 | 420303 | 420368 |

| Air/Air | 420200 | 420291 | 420365 | 420288 | 420314 | 420294 | 420368 | |

| 60 A | N2/N2 | 420200 | 420309 | 420365 | 420297 | 420323 | 420303 | 420368 |

| F5/N2 | 420200 | 420309 | 420365 | 420297 | 420323 | 420303 | 420368 | |

| N2/H2O | 420200 | 420300 | 420365 | 420296 | 420323 | 420303 | 420368 | |

| Air/Air | 420200 | 420309 | 420365 | 420297 | 420323 | 420294 | 420368 | |

| 80 A | N2/N2 | 420200 | 420309 | 420365 | 420306 | 420323 | 420303 | 420368 |

| F5/N2 | 420200 | 420309 | 420365 | 420306 | 420323 | 420303 | 420368 | |

| N2/H2O | 420200 | 420300 | 420365 | 420290 | 420323 | 420303 | 420368 | |

| Air/Air | 420200 | 420309 | 420365 | 420306 | 420323 | 420294 | 420368 | |

| 130 A | N2/N2 | 420200 |

420318 |

420365 |

420315 |

420314 | 420356 | 420368 |

| H2-Ar-N2/N2 | 420200 | 420318 | 420365 | 420315 | 420323 | 420356 | 420368 | |

| N2/H2O | 420200 | 420469 | 420365 | 420315 | 420314 | 420356 | 420368 | |

| 170 A | N2/N2 | 420200 | 420327 | 420365 | 420324 | 420314 |

420356 |

420368 |

| H2-Ar-N2/N2 | 420200 | 420327 | 420365 | 420324 | 420323 | 420356 | 420368 | |

| N2/H2O | 420200 | 420472 | 420365 | 420324 | 420314 | 420356 | 420368 | |

| Air/Air | 420200 | 420513 | 420365 | 420524 | 420260 | 420258 | 420368 |

Gouging Consumables

Mild Steel

| Amperage | Process | Shield cap | Shield | Nozzle retaining cap |

Nozzle* | Swirl ring | Electrode | Water tube |

|---|---|---|---|---|---|---|---|---|

| 170A | O2/Air | 420200 | 10086659 | 420365 | 10087904 (.140) Bore | 420242 | 10086653 | 420368 |

| 300A | O2/Air | 420200 | 10086659 | 420365 | 10086655 (.180) Bore | 420242 | 10086653 | 420368 |

| 460A | O2/Air | 420200 | 10086659 | 420365 | 10086657 (.195) Bore | 420242 | 10086653 | 420368 |

*Reference "XPR Gouging Charts for Nozzle"

XPR170 starter kits

| Part number | Description |

|---|---|

| 428842 | XPR170 mild steel consumables starter kit (torch included) |

| 428841 | XPR170 non-ferrous consumables starter kit (torch included) |

| 428840 | XPR170 mild steel consumables starter kit |

| 428843 | XPR170 non-ferrous consumables starter kit |

| 428944 | XPR170 Core console non-ferrous consumables starter kit |