SmartSYNC torches

With simple, twist-on consumable installation, and convenient power and amperage adjustment controls on handheld models, SmartSYNC® torches for Hypertherm’s Powermax45/65/85/105 SYNC® plasma systems, and Powermax45® XP with adapter, allow the operator to change consumables and applications without returning to the power supply. This reduces consumable change time to about 10 seconds and automatically sets the system for the cartridge, minimizing downtime, troubleshooting, waste and training time.

Torch information

Applications

Drag cutting

For dragging the torch directly across the work piece

Extended reach cutting

For improved visibility and accessibility when cutting in confined spaces

Extended reach gouging

For improved visibility and accessibility when gouging in confined spaces

Mechanized cutting

For portable automation and table cutting

Benefits

For handheld cutting and gouging jobs

The time-saving SmartSYNC torch controls allow the operator to adjust the amperage on the fly and change consumables and applications without returning to the power supply. SmartSYNC 75° and 15° hand torches are well-suited for a variety of applications such as gouging, fine feature cutting, extended reach cutting, and flush cutting. The ergonomic design of the 75° torch is perfect for normal cutting, while the 15° torch directs heat away from the operator during heavy gouging and enables cutting overhead or in hard-to-reach areas.

For machine jobs

SmartSYNC torches with the Hypertherm cartridge automatically set the correct amperage and operating mode, eliminating setup errors. SmartSYNC full-length machine torches work with a wide variety of CNC cutting tables, track cutters, and pipe-cutters. Mini-machine torches are perfectly suited for lighter tables and pipe-cutting operations where the full-length torch is too long.

For robotic jobs

The light weight, small size, and built-in positioning features of SmartSYNC robotic/mini torches enable easy integration and operation with light robot arms. Optional clamps and teach tools speed up integration.

For extended reach cutting jobs

Hypertherm offers five new SmartSYNC long torches in two different lengths – 0.6m (2′) and 1.2 m (4′) – and two different torch head angles – 45° and 90° – for extended reach cutting jobs including skeleton cutting, scrapping, and demolition. Compared to the first-generation Duramax® Hyamp® long torch, these torches require 45% less lifting force to make the operator’s job easier, and they have gone through extensive design and testing to make them even more robust. A flexible lead also makes these torches more ergonomic and easier for the operator to maneuver.

Buying information

Visit our where to buy page to find a potential partner, or contact Hypertherm directly if you need further assistance.

SmartSYNC torches

|

|

Hand torches |

Machine torches |

Robotic/Mini |

Long torches |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

|

75° |

15° |

180° |

180° |

90° |

45° |

0,6 m (2′), 45° |

0,6 m (2′), 90° |

1,2 m (4′), 45° |

1,2 m (4′), 90° |

|

4,5 m (15′) |

|

|

|

059733 |

|

|

|

|

|

|

|

7,6 m (25′) |

059726 |

059723 |

059719 |

059734 |

059731 |

059729 |

|

|

528114 |

|

|

10,7 m (35′) |

|

|

059720 |

|

|

|

|

|

|

|

|

15,2 m (50′) |

059727 |

059724 |

059721 |

059735 |

059732 |

059730 |

528116 |

528117 |

528118 |

528119 |

|

22,8 m (75′) |

059728 |

059725 |

059722 |

|

059767 |

059766 |

|

|

|

|

Resources

Manuals and documents

Hypertherm Cartridges

The Hypertherm cartridge consumable platform is a revolutionary change to standard air plasma consumables. Each single-piece cartridge is optimized by process and amperage to ensure performance while dramatically simplifying the parts needed to cut or gouge with plasma.

Hypertherm cartridges for Powermax systems are manufactured to uphold our high standards for quality and reliability. As part of the manufacturing process, we test-fire each cartridge to ensure proper assembly and function. As a result, there may be burn marks on the tip of the cartridge. This is normal and not a sign of damage.

Drag cutting and FineCut for hand torches

|

Hypertherm cartridges |

|

|

Process |

Cartridge |

|

105 A |

|

|

85 A |

|

|

65 A |

|

|

45 A |

|

|

FineCut® hand cutting |

|

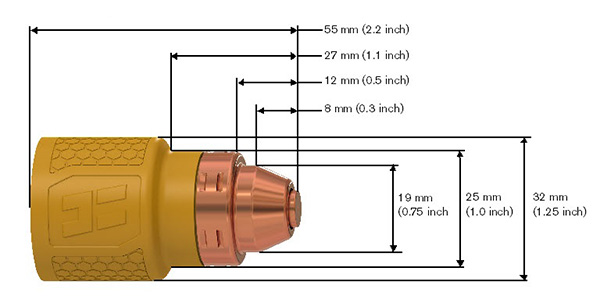

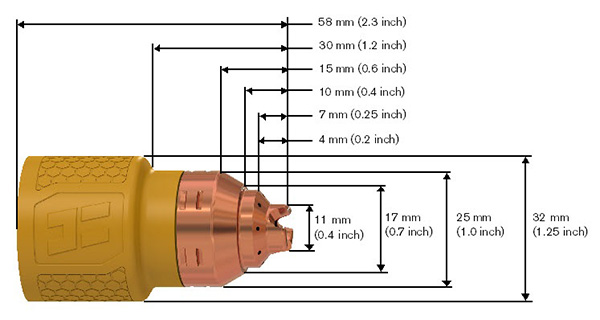

These cartridges have different dimensions as compared to traditional consumables which need to be factored when using cutting templates and guides.

Drag cartridge:

FineCut cartridge: