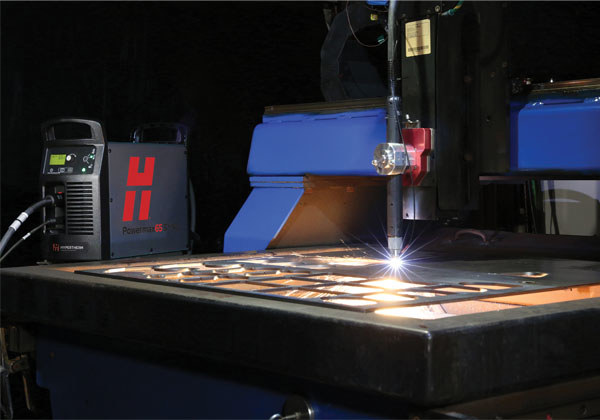

Powermax65 SYNC plasma cutter

The Powermax65 SYNC® is a next-generation professional grade air plasma cutter that dramatically simplifies system operation for gouging and recommended cutting up to 20 mm (3/4″). Featuring automated system process set-up via advanced RFID-enabled SmartSYNC® torches and a revolutionary single-piece cartridge consumable that provides trackable utilization data. The Powermax65 SYNC maximizes productivity through reductions in downtime, optimized cut quality performance and streamlined consumable inventory management.

System information

Applications

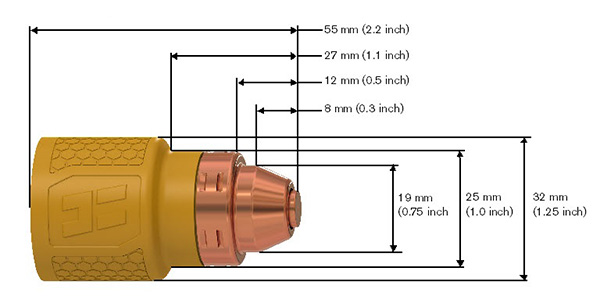

Drag cutting

For dragging the torch directly across the work piece

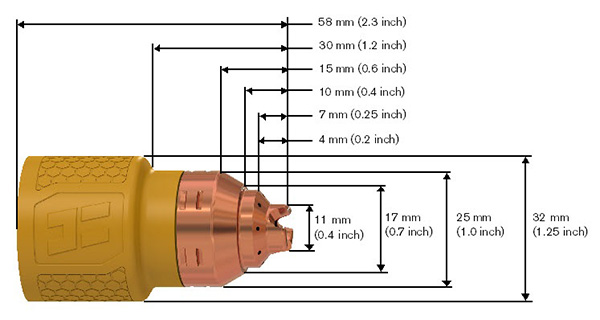

Extended reach cutting

For improved visibility and accessibility when cutting in confined spaces

Extended reach gouging

For improved visibility and accessibility when gouging in confined spaces

Fine feature cutting

For narrow kerf width with minimal dross and heat affected zone

Flush cutting

For cutting closer to base materials using a 45 degree

Max control gouging

For precise metal removal, shallower gouge profiles and light metal washing

Max removal gouging

For aggressive metal removal, deep gouge profiles, and extreme metal washing

Mechanized cutting

For portable automation and table cutting

Unsupported applications

Precision gouging

For spot and tack weld removal at very low output current (<25 A)

Try Powermax45 XP

Benefits

Easy to use

- Cartridges are easy to identify by process with clear laser marking and color coding to eliminate part mix-ups.

- RFID-enabled SmartSYNC torches and cartridges automatically set the correct amperage and operating mode, eliminating setup errors.

- End-of-life consumable detection eliminates the uncertainty of knowing when to change the cartridge.

- Less operator fatigue when using hand torches with our new flexible lead. The lead has the same robustness of our previous lead jacket material and will also be used on robotic torches.

Minimize operation costs

- Simplified system operation minimizes the time and costs spent on training and troubleshooting.

- Reductions to downtime during consumable change-outs and elimination of costs associated with premature disposal of consumable parts.

- Cartridge usage data provides valuable insights for improving cutting operations and consumable inventory management.

Maximize performance

- Tackle a wide range of jobs with easily interchangeable torch styles and application specific cartridges for various types of cutting and gouging.

- Optimized cartridge consumable design provides up to twice the life for handheld cutting and improved quality over life in mechanized setups compared to standard consumables.

- Time-saving hand torch controls allow the operator to adjust the amperage on the fly, change cartridges and applications without returning to the power supply.

Industry-leading reliability

- SmartSYNC torches are engineered for rugged, industrial environments.

- SpringStart™ technology ensures consistent starting and a more reliable torch.

- Industry-leading reliability reduces production downtime.

Specifications

Cut and gouge capacities

| Cut capacity | Thickness | Cut speed |

|---|---|---|

| Recommended | 20 mm (3/4″) | 500 mm/min (20 ipm) |

| 25 mm (1″) | 250 mm/min (10 ipm) | |

| Severance (hand cutting) | 32 mm (1-1/4″) | 125 mm/min (5 ipm) |

| Pierce* | 16 mm (5/8″) |

*Pierce rating for handheld use or with automatic torch height control

| Gouge capacity | Metal removal rate | Groove profile |

|---|---|---|

| Typical gouge | 4,0 kg (8.8 lbs.) per hour | 2,9 mm D x 6,4 mm W (0.11″ D x 0.25″ W) |

General specifications

Specifications - CSA |

|

|---|---|

|

Input voltages (± 10%) |

200–480 V, 1-PH, 50/60 Hz 200–600 V, 3-PH, 50/60 Hz |

|

Input current @ 9 kW |

200/208/240/480 V, 1-PH 52/50/44/22 A 200/208/240/480/600 V, 3-PH 32/31/27/13/13 A |

|

Output current |

20–65 A |

|

Rated output voltage |

139 VDC |

|

Duty cycle @ 40° C (104° F) |

50% @ 65 A, 230–600 V, 1/3-PH 40% @ 65 A, 200–208 V, 1/3-PH 100% @ 46 A, 230–600 V, 1/3-PH |

|

Open circuit voltage (OCV) |

295 VDC |

|

Weight with 7.6 m (25′) torch |

27.8 kg (61.7 lbs.) |

CSA – for use in the Americas and Asia, except China

Specifications - CE/CCC |

|

|---|---|

|

Input voltages (± 10%) |

380–400 V, 3-PH, 50/60 Hz |

|

Input current @ 9 kW |

380/400 V, 15.5/15 A |

|

Output current |

20–65 A |

|

Rated output voltage |

139 VDC |

|

Duty cycle @ 40° C (104° F) |

50% @ 65 A, 380–400 V, 3-PH 100% @ 46 A, 380–400 V, 3-PH |

|

Open circuit voltage (OCV) |

295 VDC 270 VDC |

|

Weight with 7.6 m (25′) torch |

24.1 kg (52.7 lbs.) |

CE – for use in Europe, Australia & New Zealand - RCM, Serbia, UK – UKCA, Ukraine, and other countries where accepted. CCC – for use in China.

|

Dimensions with handles |

483 mm D; 233 mm W; 430 mm H (19″ D; 9.2″ W; 17″ H) |

|---|---|

|

Gas supply |

Clean, dry, oil-free air or nitrogen |

|

Recommended inlet gas flow rate |

Cutting: 210 I/min @ 5.9 bar (450 scfh, 7.5 scfm @ 85 psi) Gouging: 210 I/min @ 4.8 bar (450 scfh, 7.5 scfm @ 70 psi) |

|

Electrical efficiency |

91.2% |

|

Recyclability |

100% |

|

Warranty |

Power supply: 6-year Torch: 1-year |

Buying information

ORDERING INFORMATION - CSA (For use in the Americas and Asia, except China)

Below are the standard system configurations, which include a power supply, torch or torches, work cable, 3-4 cartridges, and product information. Some configurations may include additional items such as a remote pendant and communication cables.

|

75° hand torch |

75° and 15° |

|

180° full-length |

180° full-length machine torch |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Torch lead length |

7,6 m |

15,2 m (50′) |

7,6 m |

|

7,6 m |

10,7 m |

15,2 m |

10,7 m/7,6 m |

||

|

X = With remote pendant |

|

|

|

|

X |

|

|

X |

|

X |

|

Powermax65 SYNC power supplies |

Handheld |

Mechanized | ||||||||

|

200-480 V CSA standard power supply |

083343 |

083344 |

083347 |

|

|

|

|

|

|

|

|

200-480 V CSA power supply with CPC port and voltage divider |

083345 |

083346 |

|

|

083348 |

083349 |

|

083361 |

083350 |

083351 |

|

200-480 V CSA power supply with CPC port, voltage divider, and serial port |

|

|

|

|

083352 |

083375* |

|

083376* |

|

|

* Ring terminated worklead

CUSTOM CONFIGURATIONS - CSA

Select power supply, torch, work cable, cartridge, and other components.

|

Power supply option |

Standard |

With CPC port and voltage divider |

With CPC port, voltage divider and serial port |

|---|---|---|---|

| Powermax65 SYNC 200-600 V CSA |

083371 |

083372 |

083373 |

ORDERING INFORMATION - CE/CCC

(CE - For use in Europe, Australia & New Zealand - RCM, Serbia, UK - UKCA, Ukraine, and other countries where accepted. CCC - for use in China.)

Below are the standard system configurations, which include a power supply, torch or torches, work cable, 3-4 cartridges, and product information. Some configurations may include additional items such as a remote pendant and communication cables.

|

75° hand torch |

75° and 15° |

|

180° full-length |

180° full-length machine torch |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Torch lead length |

7,6 m |

15,2 m (50′) |

7,6 m |

|

7,6 m |

10,7 m |

15,2 m |

10,7 m/7,6 m |

||

|

X = With remote pendant |

|

|

|

|

X |

|

|

X |

|

X |

|

Powermax65 SYNC power supplies |

Handheld |

Mechanized | ||||||||

|

380-400 V CE/CCC standard power supply |

083356 |

083357 |

083360 |

|

|

|

|

|

|

|

|

380-400 V CE/CCC power supply with CPC port and voltage divider |

083358 |

083359 |

|

|

083362 |

083327 |

|

083363 |

083364 |

083365 |

|

380-400 V CE/CCC power supply with CPC port, voltage divider, and serial port |

|

|

|

|

|

083366 |

083377 |

|

083367 |

|

CUSTOM CONFIGURATIONS - CE/CCC

Select power supply, torch, work cable, cartridge, and other components.

|

Power supply option |

Standard |

With CPC port and voltage divider |

With CPC port, voltage divider and serial port |

|---|---|---|---|

| Powermax65 SYNC 380-400 V CE/CCC |

083368 |

083369 |

083370 |

~ AVAILABLE FOR ALL SYSTEMS ~

Torch options

View the Torches and Consumables section below for torch and cartridge options.

Cable options

|

Control cables |

||||||

|---|---|---|---|---|---|---|

|

Cable length |

Remote pendant |

CNC, spade connector, divided voltage |

CNC, spade connector, no divided voltage |

CNC, D-sub connector, divided voltage |

RS-485 Serial comm, unterminated |

RS-485 Serial comm, D-sub |

|

7,6 m (25') |

128650 |

228350 |

023206 |

223048 |

223236 |

223239 |

|

15,2 m (50') |

128651 |

228351 |

023279 |

123896 |

223237 |

223240 |

|

22,8 m (75') |

128652 |

|

|

|

|

|

|

Work leads |

|||

|---|---|---|---|

|

Cable length |

Hand clamp |

C-style clamp |

Ring terminal |

| 7,6 m (25') |

223035 |

223203 |

223209 |

|

15,2 m (50') |

223034 |

223204 |

223210 |

|

22,8 m (75') |

223033 |

223205 |

223211 |

Resources

Manuals and documents

SmartSYNC torches

SmartSYNC torches feature RFID capability that when coupled with a Hypertherm cartridge will communicate with a Powermax SYNC system to automatically set the amperage and process on the power supply. Available in handheld, mechanized and robotic torch configurations.

|

|

Hand torches |

Machine torches |

Robotic/Mini |

|||

|---|---|---|---|---|---|---|

|

|

75° |

15° |

180° |

180° |

90° |

45° |

|

4,5 m (15′) |

|

|

|

059733 |

|

|

|

7,6 m (25') |

059726 |

059723 |

059719 |

059734 |

059731 |

059729 |

|

10,7 m (35') |

|

|

059720 |

|

|

|

|

15,2 m (50') |

059727 |

059724 |

059721 |

059735 |

059732 |

059730 |

|

22,8 m (75') |

059728 |

059725 |

059722 |

|

059767 |

059766 |

|

30 m (100') |

059770 |

|

|

|

|

|

|

|

Long torches |

|||

|---|---|---|---|---|

|

|

0,6 m (2′), 45° |

0,6 m (2′), 90° |

1,2 m (4′), 45° |

1,2 m (4′), 90° |

|

4,5 m (15′) |

|

|

|

|

|

7,6 m (25') |

|

528114 |

|

|

|

10,7 m (35') |

|

|

|

|

|

15,2 m (50') |

528116 |

528117 |

528118 |

528119 |

|

22,8 m (75') |

|

|||

Hypertherm cartridges

The Hypertherm cartridge consumable platform is a revolutionary change to standard air plasma consumables. Each single-piece cartridge is optimized by process and amperage to ensure performance while dramatically simplifying the parts needed to cut or gouge with plasma.

Hypertherm cartridges for Powermax systems are manufactured to uphold our high standards for quality and reliability. As part of the manufacturing process, we test-fire each cartridge to ensure proper assembly and function. As a result, there may be burn marks on the tip of the cartridge. This is normal and not a sign of damage.

Drag cutting and FineCut for hand torches

Mechanized and FineCut for machine torches

Max removal and max control gouging

FlushCut options

|

Hypertherm cartridges |

|

|

Process |

FlushCut™ |

| 65 A | |